sales@sanshinechina.com

sales@sanshinechina.com WhatsApp

WhatsApp sanshineelectronics

sanshineelectronics 673469847

673469847 0086-592-6603065

0086-592-6603065

Fully automatic multi-spindles linear coil winding machine

16 spindles coil winding machine within tape wrapping and wire twisting system

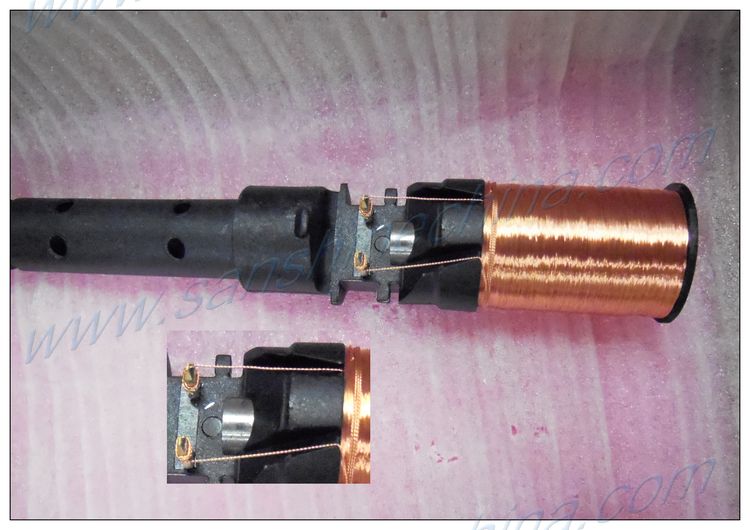

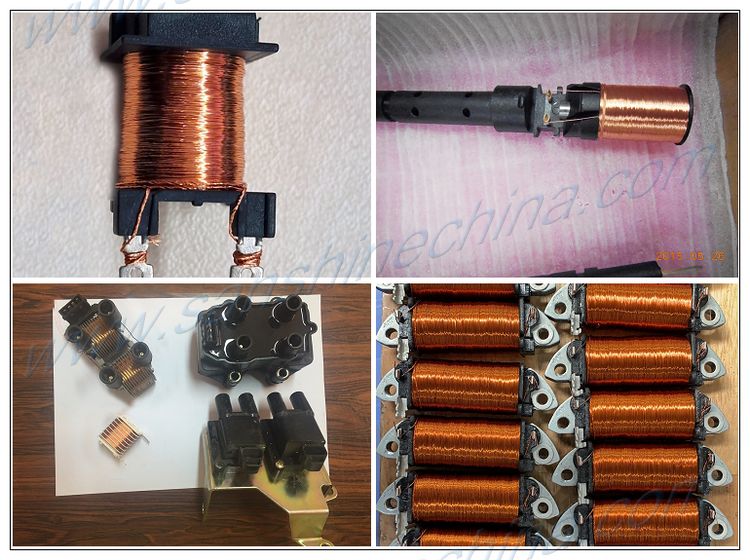

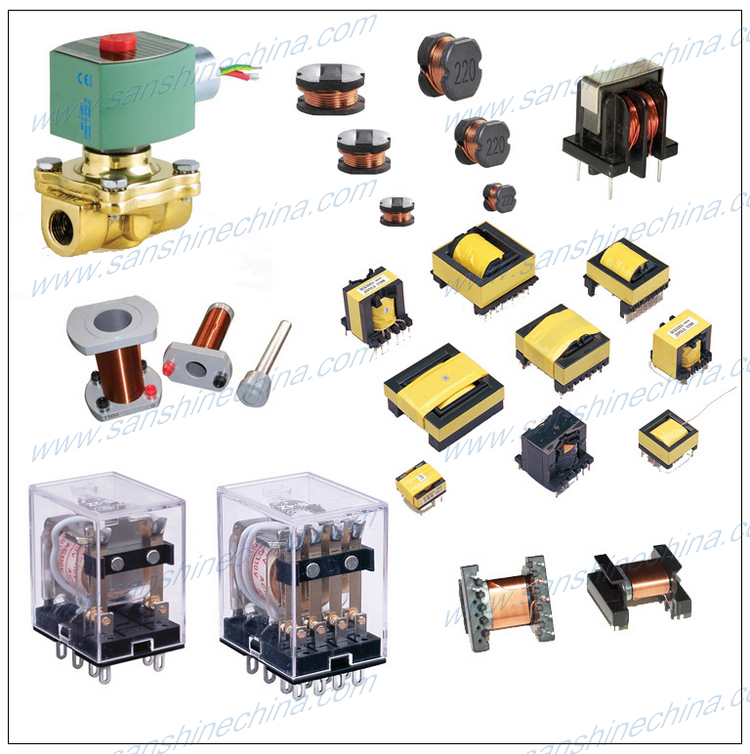

Finished products show

Description :

The fully automatic multi-spindles linear coil winding machine is used for winding the small power transformers, signal transformers, inductors, filter choke coil, relays, current contactors, valve coils, solenoid coils, telecom transformers. It can complete the coils without any one operator in fully automatically. Do the bobbins loading and finished coils unloading, winding, twisting, tape wrapping, wire cutting, wire stripping actions fully automatically quickly with different function optional system. Make your production quality and efficiency to top grade.

Fixtures :

1),Specially wire cutting system for thick wire and TEX wire.

2),The wire clips can hold wire still automatically when air pressure cut off.

3),Can cut off air pressure automatically when electric power off.

4),Can wind multiple piece wires in parallelly at same time on same bobbin.

5),Calibrate the original position of X / Y / Z spindles automatically.

6),Automatically loading and unloading function.

7),Wire broken alarm function.

8),Wrapping tape function.

9),Wire twisting function.

10),Wire cutter cutting function.

11),Wire stripping function.

12),High precise servo motors with high precise controlling system and movement system.

13),Multi-angles to wind wire terminal on the pins.

14),Winding jigs and loading /unloading fixture can be changeable easily.

15),Chinsee / English operation interface switchable with touching screen.

16),Potable adjustment keyboard.

Specification :

| Model | SS1206 | SS8008 | SS1208 | SS7010 | SS9910 | SS6012 | SS8012 | SS4516 | SS6016 | SS3824 | SS3532 |

| Spindle numbers | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 16 | 16 | 24 | 32 |

| Center distance between spindles | 120mm | 80mm | 120mm | 70mm | 99mm | 60mm | 80mm | 45mm | 60mm | 38mm | 35mm |

| Max. Dia. Or width of bobbin | 55mm | 50mm | 55mm | 45mm | 50mm | 42mm | 45mm | 30mm | 42mm | 20mm | 16mm |

| Wire diameter (mm) | 0.02 ~ 0.8 | 0.02 ~ 0.6 | 0.03 ~ 0.6 | 0.02 ~ 0.5 | 0.03 ~ 0.5 | 0.02 ~ 0.45 | 0.02 ~ 0.5 | 0.02 ~ 0.35 | 0.02 ~ 0.35 | 0.02 ~ 0.35 | 0.02 ~ 0.3 |

| Control way | Precise CNC multi-axis AC servo motor transmission system, position controlling precisely. | ||||||||||

| Spindles rotating speed (RPM) | Max. 9000 | Max. 9000 | Max. 7000 | Max. 9000 | Max. 8000 | Max. 12000 | Max. 8000 | Max. 12000 | Max. 10000 | Max. 12000 | Max. 15000 |

| Winding nozzle angle | 0° , 90° , 45°(optional) | ||||||||||

Spindles rotating angle | 360° ±0.1 | ||||||||||

| Traverse range of winding nozzle | (X Axis):0-100mm (Y Axis):0-100mm (Z Axis):0-60mm | ||||||||||

| Accuracy of winding nozzle movement | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

X / Y / Z Axis servo motor power (KW) | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 | (X):0.4 (Y):0.4 (Z):0.4 |

Wire terminal clips device moving servo motor power | 400W | 400W | 400W | 400W | 400W | 400W | 400W | 400W | 400W | 400W | 400W |

Winding spindle servo motor power | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 2.0KW | 2.0KW |

| Operation interface | Easily and simply teaching model operation system (Chinese / English operation interface switchable with touching screen) | ||||||||||

| Program storage method | Direct storage + USB | ||||||||||

Power supply | Single phase AC220V 50/60 Hz or AC110V 50/60 Hz by request | ||||||||||

| Power | 3KW | 3KW | 3.5KW | 3KW | 3.5KW | 3KW | 3.5KW | 3KW | 3.5KW | 3.5KW | 3.5KW |

| Air source pressure | 5-6Kgf/cm2 | ||||||||||

| Servo motor | Panasonic or or FUJI or YASKAWA | ||||||||||

| Cylinder | SMC / CKD /Airtac / Chelic Cylinder | ||||||||||

| Machine net weight | 650Kg | 650Kg | 750Kg | 650Kg | 750Kg | 650Kg | 750Kg | 650Kg | 750Kg | 900Kg | 900Kg |

Machine size with tensioners shelf (W*L*H) | 1500* 1200* 1820 mm | 1700* 1500* 1650 mm | 1500* 1200* 1820 mm | 1700* 1500* 1650 mm | 1500* 1200* 1820 mm | 1700* 1500* 1650 mm | 1500* 1200* 1820 mm | 1700* 1500* 1650 mm | 1200* 1500* 1600 mm | 1700* 1500* 1650 mm | |

Bobbing loading and finished coil unloading way | Operator place bobbins on the Auto. Loading and unloading fixture first, then machine insert the bobbins onto the winding spindles automatically, will unload the finished coils automatically. ( fully automatic loading and unloading bobbins and coils function by request to customize, fully automatically loading and unloading function which no need operator to place the bobbins on the fixture. These winding machines can be integrated with our automatic solder tinning machines and automatic testing machines and core assembly machines so that to be one fully automatic finished coils production line without operator. we provide the fully automatic finished coils production line by user request.) | ||||||||||

| Tape wrapping function | optional | optional | optional | optional | optional | optional | optional | optional | optional | NO | NO |

| Wire twisting function | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional |

| Thick wire cutter cutting function | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional |

| Wire stripping function | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional |

| Wire broken alarm function | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional |

0086-592-6603065

0086-592-6603065

0086-592-3761682

0086-592-3761682

0086-138 60450316

0086-138 60450316