sales@sanshinechina.com

sales@sanshinechina.com WhatsApp

WhatsApp sanshineelectronics

sanshineelectronics 673469847

673469847 0086-592-6603065

0086-592-6603065

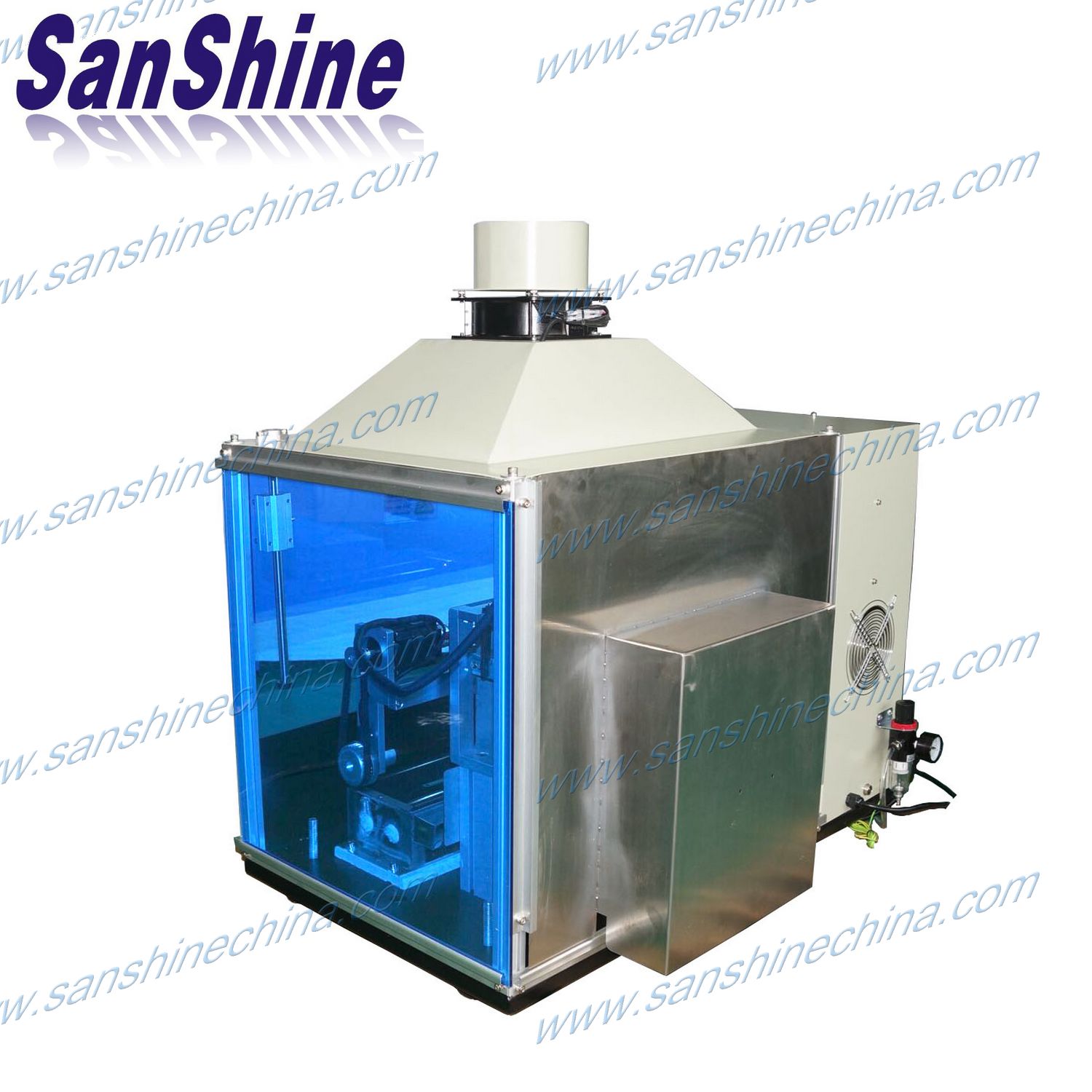

Product : Touching screen type three axes multifunctional angle able automatic solder coil tinning machinery (SS-RT01SC)

Description :

The touching screen type three axes multifunctional angle able automatic solder coil tinning machinery (SS-RT01SC)

adopts precise digital tinning controller and servo motors. Has porogrammable digital two axes which hold the tinning

components to up, down, front, behind and turnning in 360 radian during tinning or before tinning or after tinning.

This multifunction tinning machine can take the soldering components to be an angle first before its pins or terminals be

inserted (dipped) into the liquid solder then go to tin. The dipping angle, dipping depth, dipping time, dipping temperature

are programmable easily by user. This soldering machiney (SS-RT01SC) can substitute the SS-RT01 and SS-VT01

machine fully. This solder tinning machiney is called electronic electric component pins terminals tinning machine, linear

motor terminal solder tinning machine, inductor transformer relay valve winding coils terminal solder tinning machine also.

This digital automatic tinnig machine is best choice for soldering the SMT electronic components and planar coils (SMT /

SMD transformers inductors, chokes.) and vertical pins transformers inductors relays valves which request soldering

(tinning) at an angle in the liquid solder or request the precise tin tip after tinning.

User no need open the angle function if user no need it.

Feature :

1. Big touching screen and multifunction and multi-purpose automatic soldering machine by angle-able.

2. Most suitable for soldering SMD and vertical components or planar coils ( Inductors, transformers, relays, choke,

valve coil, contactor, terminals, etc.) which request soldering at an angle or request precise tin tip.

3. Slodering tool can be turned 360 degrees to a position for tinning at any precise angle.

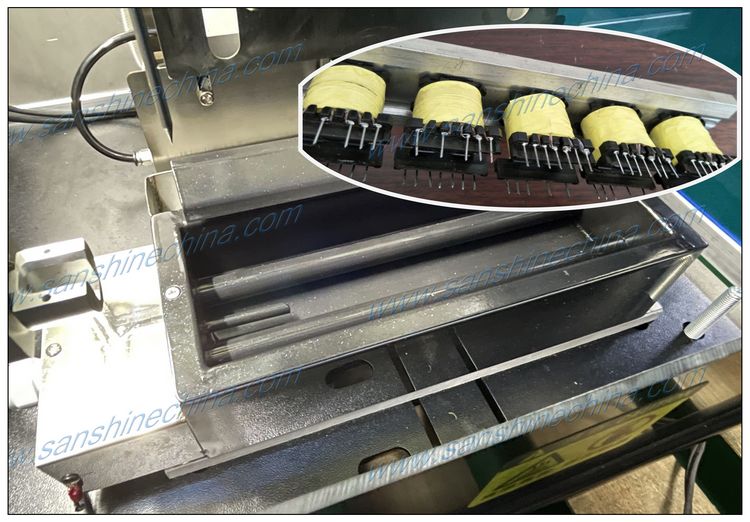

4. Multiple coils can be soldered in one cycle. Programmable precise preheating deepth, tinning deepth and time.

5. 99 steps program memory plus each program can assign 10 parameters independently.

6. The mode of each of the three sections is set by one program.

7. Each section can be provided with additional programming parameters, angle setting,

dipping depth, and pre-heating time.

8. Compact and desk-mount design. Can take the tinning pins of products to traverse in the solder

then go up in precisely.

9. Process includes position to an angle, then DIP solder, re-position to other side angle for soldering,

finally re-position to parallel for cleaning solder automatically.

10. Lead free titanium inner bath pot with coated ceramic to withstand high temperatures and reduce oxidation.

11. Lead free titanium DIP pot suitable for lead free solder. Dip pot inner size L300*W100mm*D55mm.

12. Side inserted heating tubes enable easy maintenance.

13. Automatically clean the sediment of solder before soldering.

14. Cover the tinning station fully with automatic open and close safty door to take care your operator.

15. Strong exhaust fan for cleaning the tinning smoke fastly.

16. Power source : single phase AC220V 50/60Hz, Air pressure source : 0.7Mpa.

17. Machine net weight : 60Kgs, Machine sizes: 77*62*85cm.

0086-592-6603065

0086-592-6603065

0086-592-3761682

0086-592-3761682

0086-189 6513 8473

0086-189 6513 8473